Our Scandinavian-designed Woodura Planks 3.0 are built to withstand the test of time with a unique blend of revolutionary technologies. The wood for these super-strong and dent-resistant hardened wood floors is sourced ethically and responsibly from FSC-certified European forests.

Exceptionally durable hardened wood flooring

Many times stronger and more water resistant than traditional flooring

Many times stronger

Our Woodura Planks 3.0 are empowered by several ground-breaking technologies developed in-house by sister company Välinge Innovation, creating an exceptionally durable and long-lasting experience. The combination of the surface technology Woodura, the moisture-resistant Välinge Compositek Core, and the leakproof 5G Dry floor locking system ensure a strong and water-resistant floor that can last for generations.

This hardened wood collection is available in multiple colours, sizes and surface treatments, suitable for both residential and commercial use.

A new range that commands attention

Through the fusion of technology and ageless craftsmanship, our carefully curated Contrast Collection celebrates the distinct characteristics of the renowned Spačva oak. We have pioneered a cutting-edge approach to seamlessly integrate contrasting pigments into the surface, highlighting the natural grain of the oak. Practical and aesthetically pleasing, these exceptionally durable floors suit environments bustling with activity while bringing the wow factor.

Drawing on our Scandi-inspired palette, the Contrast Collection blends harmoniously with the highly durable Hardened Wood 3.0 range.

Strong and durable with Woodura™

Our hardened wood floors – Woodura Planks 3.0 – feature the patented Woodura technology that makes it possible to compress and harden wood, producing floors that are three times stronger than traditional wood floors. The Woodura solution is an improvement on the technology used for the manufacturing of real wood floors – and it’s as revolutionary as the 3-layer parquet was in 1944.

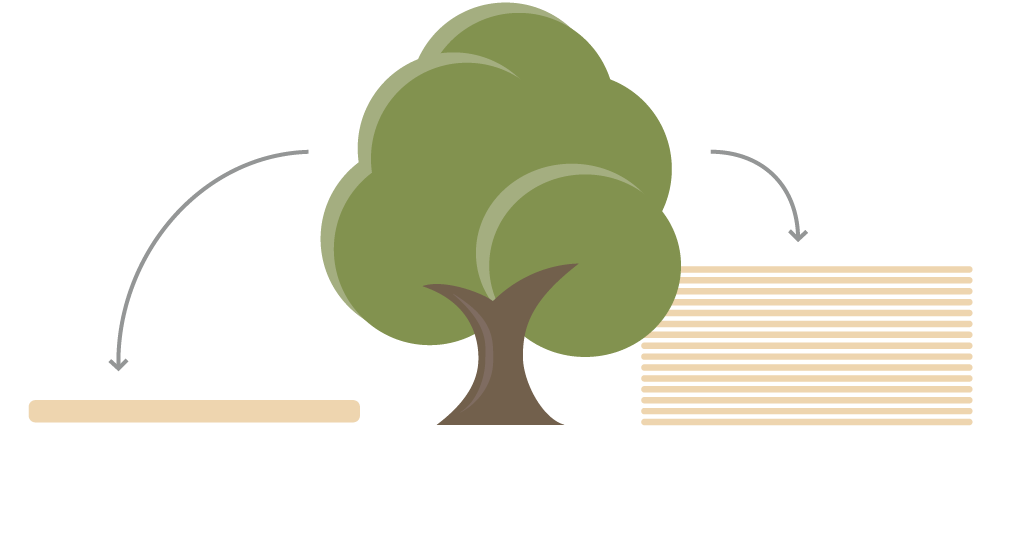

The hardening process provides a much stronger and dent- and water-resistant surface that never needs to be sanded. Using thinner surface layers in the production also enables us to create ten times more flooring from the same amount of timber. This makes the floor cost-effective while minimising the environmental impact.

The reliable wood core

Our moisture-resistant Välinge Compositek wood core is a key component in our Woodura Planks 3.0, contributing to the durable flooring experience. Rather than acting like a traditional HDF, our core has enhanced qualities. So, how does this work? When the veneer and the core are fused through our unique powder mix, a transition zone forms, providing the material with a higher surface density and improved resistance to swelling. The result is a durable, high-quality wood core.

A fast, easy, and durable installation

When developing our Woodura Planks 3.0, simplicity and everyday life were important keywords. We therefore incorporated an updated version of the easy-to-install floor locking system, 5G Fold Down.

With the new, leakproof 5G Dry installation system, you still just click the floor panels together without glue, nails or sealants – but watertight joints also prevent water from seeping through the seams and damaging the sub-floor. An installation has never been easier and more durable!

5G Dry

5G Dry is the latest innovation in floor locking technology. This unique solution was developed by our sister company Välinge Innovation, also known as the inventor of the first mechanical locking system for flooring.

5G Dry was developed to prevent water from seeping through the seams of the floor panels.

Thoroughly tested

The 5G Dry locking system has been developed to pass the ISO Topical Moisture test. During this test, the floor and joints are exposed to water for 24 hours and then 24 hours of drying. The test is often used to assess the behaviour of flooring installations exposed to water and spills.

Our Woodura Planks 3.0 meet all the requirements of ISO 4760.

Easy to install

It’s never been easier to install a water-resistant wooden floor.

With 5G Dry, you don't need any extra sealant or glue. The installation of a high-quality click floor saves both time and money. And in the unlikely event that you grow tired of the floor, it can easily be uninstalled and moved to another room.

Woodura’s Brinell performance

Experience the unmatched hardness made possible by the Woodura technology, a true game-changer in wood flooring. Compared to traditional wood floors, Woodura flooring delivers exceptional durability without compromising the natural beauty of wood. Its surface, tested using the Brinell method, showcases a strength that sets it apart.

Our 9 mm Woodura Planks are available in S, M, and L sizes, while the 11 mm options include the impressive XL, XXL and the elegant Woodura Herringbone. This innovative technology ensures your floors maintain their beauty and strength, even in the most demanding spaces.

| Wood species | Woodura 9 mm | Woodura 11 mm | Parquet | Solid wood |

| Candian Maple | 8 | 10 | 4,8 | 4,8 |

| Birch | 8 | 10 | 2,6 | 2,6 |

| Beech | 8 | 10 | 3,8 | 3,8 |

| Oak | 8 | 10 | 3,7 | 3,7 |

| Ash | 8 | 10 | 4 | 4 |

| Walnut | 8 | 10 | 3,4 | 3,4 |

Choosing a floor grading

Selecting the right floor grading is key to achieving the perfect look for your space. Floor grading refers to the natural features in wood, such as knots, colour variations and grain patterns. Whether you prefer a clean and smooth appearance or a more rustic style, each grading adds a unique character to your flooring.

For our Woodura Planks 3.0, we offer three surface treatments that provide different visual and tactile experiences, each serving a unique purpose.

Woodura Planks 3.0 with a brushed surface

Our Woodura Planks 3.0 are available in a long-awaited brushed surface that highlights the oak's structure in an elegant way. The brushed surface provides an exquisite look and is reminiscent of the structure of a natural, oiled wooden floor – but with the advantages of the lacquer, which makes the floors easier to clean and maintain.

Match the colour of the floor with the walls and textiles or create contrasts and make the home more rustic with natural grain and brushed planks.

We recommend brushed lacquered surface in residential applications.

Our tough pro matt lacquer

The new pro matt lacquer surface treatment is our best version yet, making these floors extremely durable. They are ideal for busy spaces within hotels, shops, offices and cafés – or a heavily trafficked area of your home. The pro matt lacquer finish makes the floor easy to maintain while protecting it from stains.

Our Woodura Planks 3.0 are available in many different designs. Create space with our extra-large XXL planks or an intricate pattern with smaller panels. Our sophisticated range of colours suits many interior design styles, so you can add a modern touch, an air of elegance or create a calm and soothing atmosphere.

We recommend the pro matt lacquer surface for heavy-duty residential and commercial areas.

A natural feeling with hard wax oil

Our wide planks with a hard wax oil surface have a natural structure that provides a wonderful feeling of wood. These floors should be oiled regularly to maintain their character. Should a scratch appear, this can usually be fixed with oil.

Due to the maintenance required, we recommend oiled wooden floors in bedrooms and living rooms where there is less heavy traffic. The floors work equally well in busier areas but will require more care in those spaces.

A size for everyone

Our wide XL and XXL planks are a popular choice. What’s unique about our hardened wood floors is that although wide planks are usually thick, the Woodura technology allows these floors to be wide while only 11 mm thin. This simplifies both the handling and the installation.

In 2023, we also introduced Small, Medium and Large sizes. These smaller panels, which are 9,2 mm thin, are easier to transport and provide more creative freedom. Perhaps you want to enhance the sense of space with XXL planks in a living room but choose smaller panels in a bedroom.

Different types of wood

We use FSC certified wood sourced from the lush forests of Croatia to create Woodura Planks 3.0. Our range is available in oak, ash and our newly released walnut.

Most of our floors are made from oak since this grows in abundance close to our flooring factories in Croatia. From these forests, we also source ash, which has an attractive grain and typically a lighter and warmer colour. There is an even more distinct grain in walnut, but the colour of these floors tends to be richer and darker.

A sustainable company

Our production is based on simple, yet wise, principles which ensures the sustainability of our business:

- We maximise the use of all raw material and every log. With our production systems, we can calculate the perfect way to cut the log in order to get the various sizes and shapes. Any wood that cannot be used as a surface layer for a product, is used as filling material. Nothing goes to waste.

- Any leftover material in the production can be recycled and turned into filling material in new floorings. Thus, minimising the amount of waste whilst the amount of flooring per cubic metre of raw material is maximised.

- We collect our raw material from responsibly managed forests where the wood is processed locally. This means that transports will be shorter and ensures local job opportunities.

Wood harvested in sustainably managed forests

The timber for the Woodura Planks 3.0 comes from forests that have been managed and cared for in a sustainable manner based on a very strict ecological, social and economic framework.

Visit the virtual showroom

Experience our floors without going anywhere

Actual colour and pattern may vary in reality

General and technical Information

Product composition

- Surface treatment such as brushed lacquer, pro matt lacquer and hard wax oil

- Compressed and hardened surface layer of wood

- Compressed and hardened wood-based powder layer

- Moisture resistant Välinge Compositek core

- Compressed and hardened wood-based powder layer

- Compressed and hardened balancing layer of wood

Width, length and thickness

XXL: 271 x 2378 x 11 mm

XL: 206 x 2200 x 11 mm

L: 180 x 2000 x 9.2 mm

M: 151 x 2000 x 9.2 mm

S: 151 x 1170 x 9.2 mm

Cleaning

Daily cleaning by wiping with a dry mop/vacuum is recommended.

Underfloor heating

Our floors work very well with a range of underfloor heating systems. For installation with underfloor heating, foil with age-resistant vapour barrier must be used, see our installation instructions for more information.

Cutting Instructions

We recommend cutting tools with cemented carbide inserts when cutting the floorboards.

Applications

Floors of Hardened Wood are suitable for almost all rooms in homes or commercial areas that are exposed to normal wear (such as offices, waiting rooms or shops). Floors made from Hardened Wood are not suitable for wet or damp rooms (eg. bathrooms or saunas).

Installation

The subfloor must be dry, even and firm. Uneveness larger than 3 millimetres per inbound meter and 2 millimetres per additional meter must be smoothed out. The installation instructions, which accompany the product, must be followed.

Maximise the floor space from each log

Hardened Wood is also a sustainable way to utilise the raw wood material at the maximum. By using thin layers of wood instead of thick, solid, panels, a significantly larger amount of final product can be made from every cubic meter of wood.

Transform excess material into a new floor

Sawdust Filling material for Woodura and Nadura.